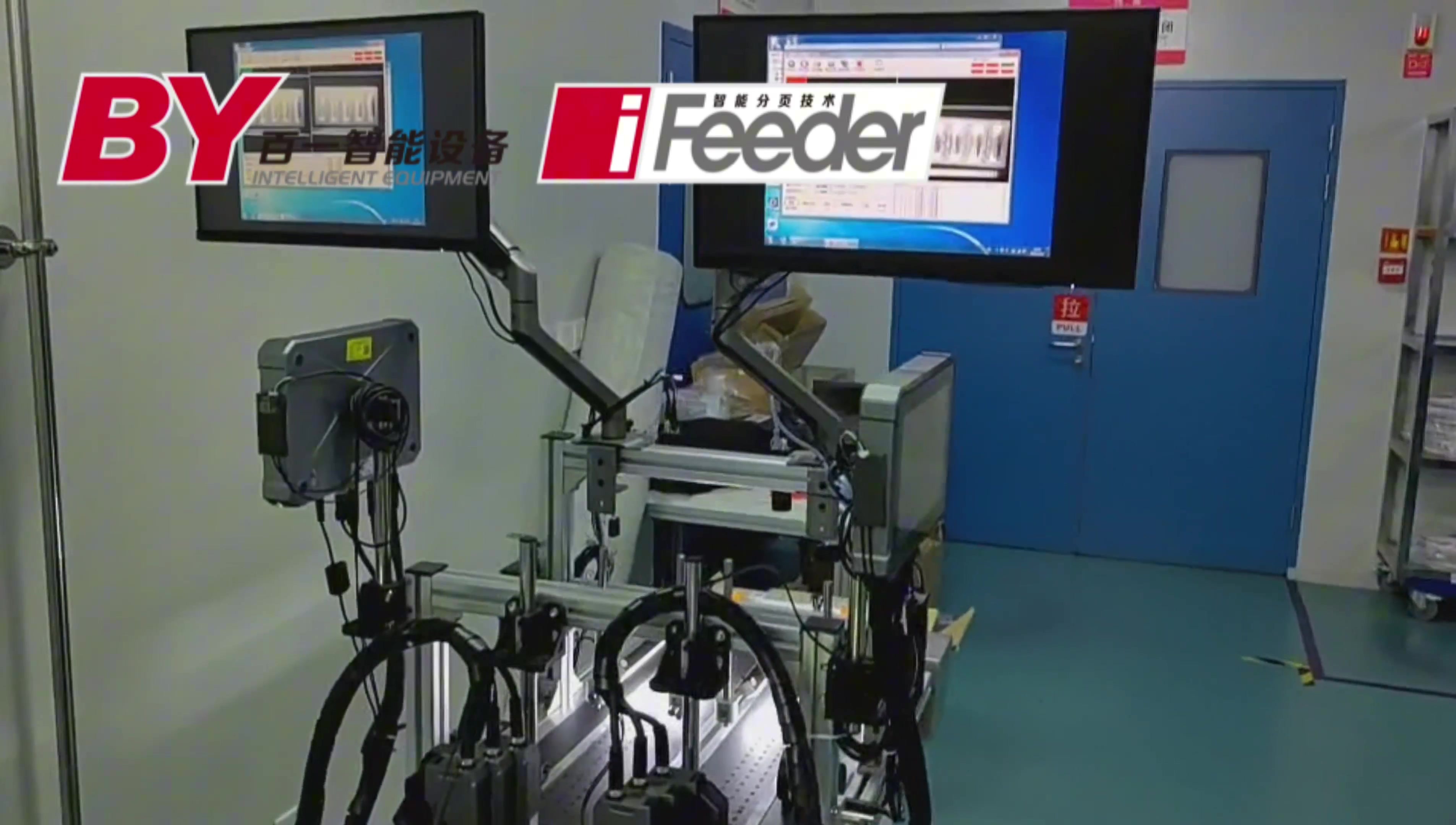

Système de détection d'impression jet d'encre d'alimentation à deux canaux

Temps de libération:

2024-04-26

Reagent bag, reagent card, etc.

During the virus outbreak in 2020, drugs were scarce, although pharmaceutical factories were still in short supply throughout the day. The efficiency of manual printing of packaged batches is far from reaching the output. We visited and learned that although each factory is constantly replenishing manual operation time,

However, the artificial physical capacity is limited, and there are areas that are constantly infected, resulting in closure and isolation and unable to produce. We actively joined the packaging and printing industry and successfully developed and manufactured: dual-channel high-speed feeding inkjet printing inspection system.

What are its components?

1. Double-channel high-speed friction feeder: as the main operation platform, it has two independent 260mm high storage bins at the same time. Workers only need to continuously stack materials into the storage bins to realize double production capacity. The products are transported to the conveyor belt one by one by friction;

After a series of inkjet printer photo tests are carried out on the conveyor belt, if the product is unqualified or not printed, the product will go directly to the automatic exit organization as the eliminated product. If the product is qualified in printing test,

Then the product can smoothly enter the qualified product storage mechanism.

2. Thermal foaming inkjet printer: the main touch screen controller consists of three nozzles (printing width 12mmX3)

3, visual inspection system: mainly composed of camera display keyboard and mouse real-time camera detection system

4. Automatic counting and storage mechanism: instead of manually counting the number of qualified products, such as a group of 10, the system will quickly and automatically identify and rearrange the replenishment if there are less than 10 unqualified products in any bin during the period.

What is the impact of this system on the production plant?

1. The speed of the automatic feeder is much higher than the speed of manual feeding, and double the production capacity is realized with the help of dual channels, and the output and efficiency are greatly deducted.

2. The visual inspection system replaces manual inspection one by one to check whether the printed content is wrong, missing or not printed.

3, automatic counting mechanism instead of manual points, saving a lot of labor costs and time.